#climate change, #environment, #sustainability

Sustainable Aviation Fuel

Sustainable aviation fuels (SAF) are defined as renewable or waste-derived aviation fuels has the greatest potential to reduce CO2 emissions from International Aviation.

Sustainable Aviation Fuel

Global passenger air travel accounts for 2.5 percent of fuel combustion-related carbon dioxide emissions.

(SAF) Sustainable alternative jet fuel results in a 19% decrease in PM2.5 damages per ton of fuel burned and a 2% decrease in total damages per ton of fuel burned as compared to damages from traditional jet fuel.

SAF Rules of Thumb

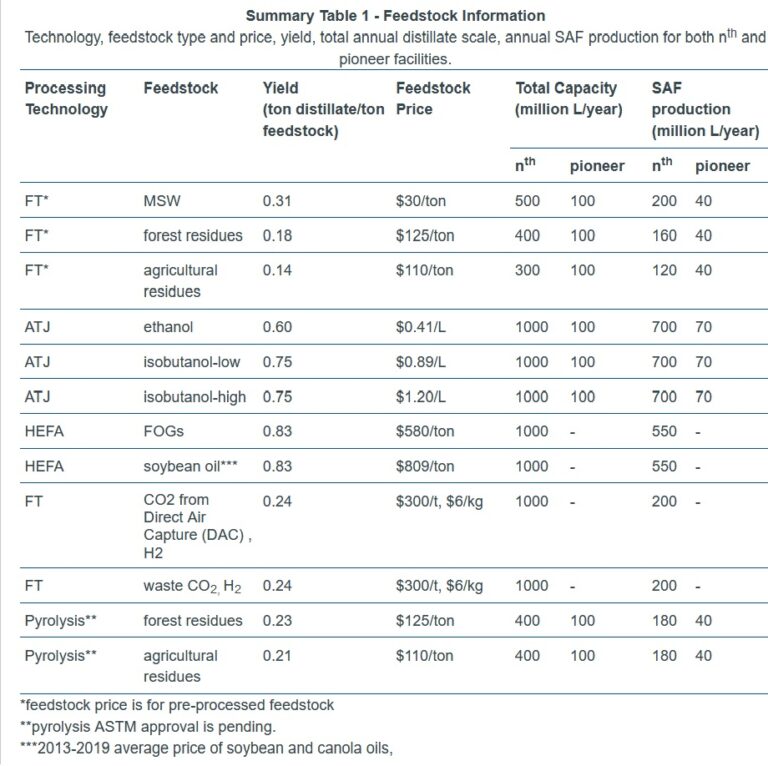

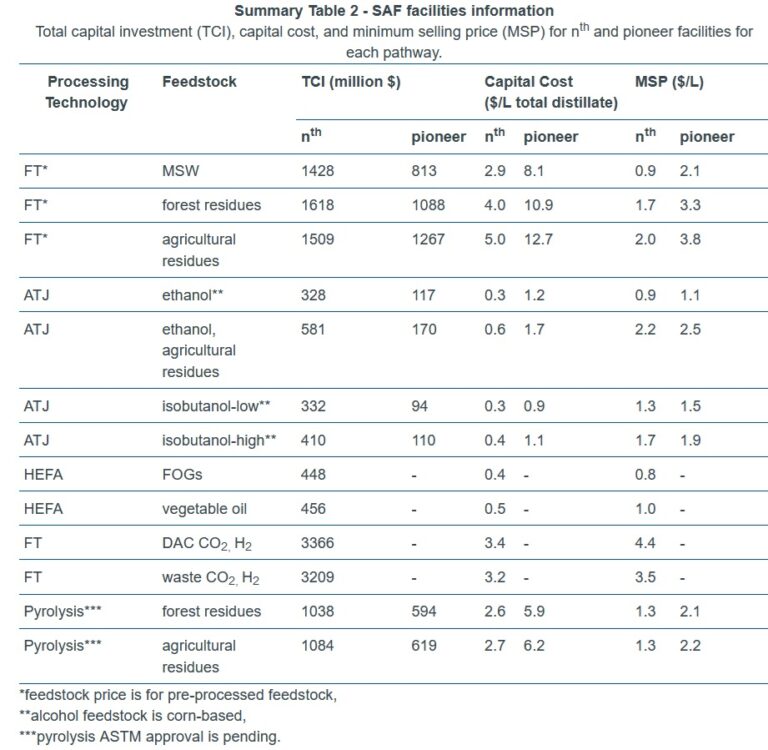

As part of work on SAF projections, CAEP experts from Washington State University, supported by experts from Hasselt University developed a set of heuristics or "Rules of Thumb" for sustainable aviation fuel (SAF) that could be utilized to make order of magnitude estimations related to SAF costs, investment needs and production potential that could inform policymakers and project developers. (Source: www.icao.int)

Enviro Bio Fuel LLC - Thailand

WHY WE DO WHAT WE DO?

Key Points.

- Aviation is 7% of UK greenhouse gas emissions (and rising). SAF reduces CO 2 by 70% compared to Fossil Fuel Kerosene. With CCUS, the Carbon Intensity (CI) profile of SAF is c. -144g/MJ, ensuring flights are carbon neutral on a 50% fuel load.

- There is a recognised shortage of SAF and the UK Govt’s new 10 Point Plan recognises the UK needs its own production capability.

- Passenger growth and climate change emphasize the need for the aviation industry to focus their efforts on sustainability.

- Recent offtake agreements for the fuel produced by the prospective Bayou Fuels plant will avoid 1.3m tonnes of CO2 a year otherwise emitted, underscoring the role that SAF will play in decarbonising the aviation sector and the journey to a net-zero economy.

- This deeply negative CI score is the lowest in the SAF industry.

- Hydrogen/Electric planes are not commercially viable, so SAF made from biomass and household/commercial waste is, at present, the only option to reduce the industry’s carbon footprint.

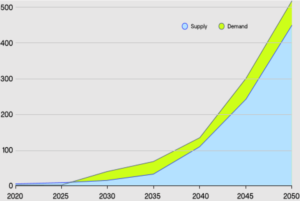

- Expected SAF demand is exponential. Based on proposed mandates in Europe, and US incentives, SAF is set to increase to 3.7bn liters pa from 2025, rising to 77.6bn liters pa by 2040 (or 600 plants equivalent).

______________ - The typical lifespan of a SAF plant is circa. 25 years

Proposed Site Location

8 Ha Site location in CHONBURI PROV..

PROJECT PROFILE

EXECUTIVE SUMMARY

SAF is a new frontier in aviation: a dream of cleaner, greener flying for all. But achieving its goals – the Net Zero ambition for 2050 and beyond – will be far from easy. This plan summarizes the relevant issues and challenges, spanning feedstock availability, production capacities, approval requirements, and the legal frameworks emerging in the two biggest aviation markets: the EU and

OPPORTUNITY

The EU’s plan for 63% blends of SAF in tanks by 2050, or the USA’s 35bn gallon production forecast for the same year highlights the real challenge for the current and future production pathways, improved collection and distribution of waste product, and capacity increases in renewable energy can indeed deliver European and American ambitions. With Thailand having one of the best regulated and strongest Agri Waste management, the opportunity to capitalize on this market demand is now. With support from the Board Of Investments in Thailand, the Private sector opportunity has never been greater

SUPPLY DEMAND FORECASTS

To date, most of the sustainable aviation fuel (SAF) activity has taken place in Europe and the United States, but there are a few new kids on the SAF block. Since the beginning of 2023, Asia Pacific has seen a surge in SAF announcements.

- SINGAPORE – Compulsory blending of SAF to begin 2026

- THAILAND – In September 2023, Thai Airways announced itwill gradually increase SAF use from 2% by 2025 to 60% by 2050.

- JAPAN – In May 2023 the government confirmed that, by 2030, 10% of aviation fuel used for international flights at Japanese airports will have to be SAF.

- NEW ZEALAND – in June 2023 the carrier and the government committed NZ$2m to further investigate the possibility of SAF production in New Zealand

GETTING IT RIGHT - COMPLETE CERTIFICATION

FOLLOWING THE ASTM RULES

The ASTM PROCESS IS A 2 STEP PROCESS – MANDATORY

TRACK 1: A 2 YEAR PROCESS THAT ALLOWS UP TO 2% BLENDING.

TRACK 2: A 4 YEAR PROCESS THAT FOLLOWS FULL COMPLIANCE AND ALLOWS UP TO 50% BLENDING +

CERTIFIED & SAFE

There are two certification paths required

- ASTM D7566: FOR SAF PRODUCTION PATHWAYS

- ASTM D4054: THE EVALUATION PROCESS FOR SAF

SUCCESS KEYS

Globally-accepted environmental Standards for SAF CORSIA includes methodologies that allow aircraft operators to reduce its offsetting requirements through the use of SAF and Lower Carbon Aviation Fuels (LCAF). These include globally-accepted sustainability criteria and life cycle methodologies. Specific details on how SAF is considered under CORSIA are provided in the ICAO Environmental Report 2019, Chapter 6 - An Overview of CORSIA Eligible Fuels (CEF). Related documents are provided in the CORSIA eligible fuels website. information on fuel batches and economic operators that are certified under CORSIA is provided on the CORSIA certified fuels website. (Source: www.icao.int)